Move power supply is difficult to learn, and there are many things to think about. Generally speaking, some power supply design processes lag behind the development of other component circuits. Because the switching power is the power supply system, we need to wait for other circuits to look for the supply voltage before designing. The design cycle associated with a power supply circuit is brief and difficult. It is a challenge for power supply development engineers.

How to learn switch power supply?

Before learning switching power supply, you should know the basic circuit knowledge, for example, analogue circuits, electromagnetic grounds, transformers, inductors, capacitors, and so forth. After these basics are understood, you can choose the right guides about switching power supply know-how to see. The first step is to know about three basic topology promenades (BUCK/BOOST/BUCK-BOOST) and the principle connected with forward and flyback promenade. Then learn more about other parts with the circuit of the switching power accessory. At least see a switching power accessory diagram to know the position of each circuit. Finally, it would be best to consider how to draw PCB. Power accessory boards are generally used sole panels. Learning to use Altium Designer is enough. It is best to use a power simulation program, which is sabre simulation.

How to develop switching power supply?

- The best way to design a switching power supply considerably better and faster is to train. It is best to enter a company with industry experts developing power supplies, not just to participate in projects but also for being taught by professionals.

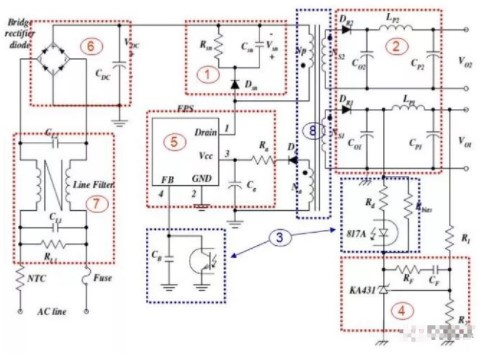

And here is a brief explanation of the different parts of a switching circuit.

Transferring power supply probably has the next components.

①RCD buffer routine: used to clamp the transformer leakage caused by the power moving over tube Drain level résistance is too high;

②Output changer filter circuit: rectify AC=> DC output;

③Optical coupling feedback circuit: Optical coupling can achieve high voltage electromagnetic isolation;

④TL431 current opinions circuit: The part of the output résistance regulation feedback circuit;

⑤PWM chopper circuit: to adjust the outcome voltage by adjusting the work cycle;

⑥Input rectifier component: 220AC=> 310DC;

⑦Input defence / EMC protection routine: to prevent damage to the routine when the circuit is unusual, EMC considerations in tough environments;

⑧Transformer: voltage conversions, energy conversion.

Next, refer to the design steps of SMPS of FLYBACK type.

- Technological specifications: the designer is required to attain the electrical performance, like size, price and EMC operating conditions

- Black container calculation: according to the use of the function to calculate the peak existing power and other elements of power work

- Transformer design: in line with the power and IC functioning frequency to design the transformer primary winding, according to the resulting voltage and the number of result groups to design the second winding, and according to the precise elements to measure often the wire gauge; (design concentration: transformer coil leakage inductance to determine the quality of power)

- Output rectifier filter: Choose the most cost-effective circuit rectifier filter depending on the selection of TOPO and production voltage. Separate capacitors to select a small ESR, or multiple capacitors with parallel to reduce ESR, can help output ripple;

- IC: Depending on the output power selection IC, working at 67KHz, the 30W-100W output is generally selected STA series

- Controller/drivers circuit: IC integrated management/drive system; consequently, there is no need for individual style and design.

- Output feedback: When the production stability needs to consider the consistency response, the use of TL431 tough a current feedback double picture than the use of three-type opinions loop design is simpler, much easier to establish; (design difficulties: the particular feedback loop to determine the steadiness of the power supply)

- Start circuit: IC VCC circuit and also circuit design on each process module

- Protection circuit: style and design over-current and over-voltage safeguard according to the peak current with the system

- Thermal analysis in addition to design: according to TOPO projected efficiency of heat dissipation, to help estimate the working temperature connected with key components, to determine regardless of if the need to install a heatsink along with the size of the heatsink; (heatsink size is related to the cost in addition to PCB size, such as the scenario of the oversized heatsink, you must return to the previous stage to help redesign)

- PCB layout: observe the circuit layout; (design complications: PCB layout often determines the EMI system and the life connected with component)

①SMPS layout is often divided into four major ways, input, power switch, output modifier, output. The four really should be separated from each other.

②Power and output should be connectors.

12.Test: Test all effectiveness indicators and improve these individuals, and seek CI

13. EMI/RFI testing: EMI/RFI must meet the actual requirements of the exporting land.

Read Also: 3 Tips on Why You Need to Start Journaling Right Now