Level D Suits Details:

Level D Suits – Choosing the right type of protective fit involves finding the perfect combination regarding comfort and safety. You want a thing that is easy to work in, just about all needs to meet the safety specifications in your area. This means deciding the degree of risk the suit must be rated at as well as the substance characteristics of the plastic fit all come into play.

Risk Ranges

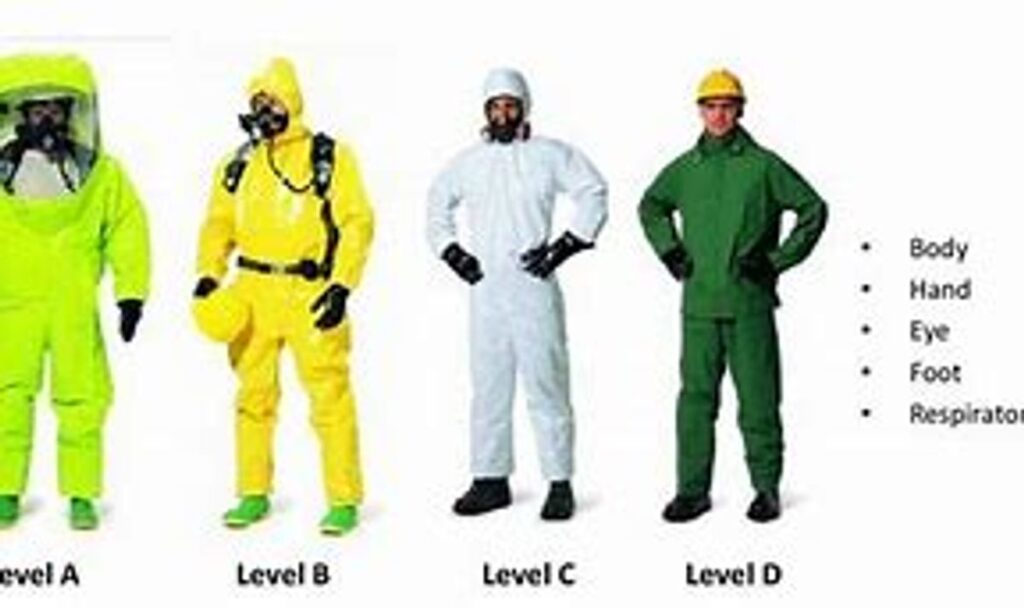

Level D Suits – The lowest level, D, will be where the situation involves simply no actual risk or threat. This level of protective fit simply needs to cover your current clothing and skin. Additional items for this level contain such as safety boots, gloves, tough hats, masks, and defends. The next level of risk, stage C, is reserved for scenarios where you know what the element is and there is some natural gas or vapors. Along with a hooded plastic suit or non-reusable coveralls, you will also need the air-purifying mask, element-resistant gloves, boots, even a hard hat.

Level D Suits – Level F involves the utmost in asthmatic protection, but it doesn’t involve quite as much in terms of defending your clothing and body. At this level, you will need to use a chemical resistant protective fit with, inner and outer devices, steel-toed and element resistant boots, and a positive-pressure self-contained breathing apparatus.

As a way to protect yourself from chemicals, vapors, and unknown elements, you will need to select Level A new protection. Chemical resistant devices and boots are associated with a gas-tight suit as well as a positive pressure self-contained breathing in apparatus. This is the highest higher level of breathing and skin safeguard available.

Protective Material

Level D Suits – A new protective suit has several main factors that establish its level of safety. One thing to consider is how the fit with is put together. Seams that happen to be sewn together have microscopic holes where the needle went through that will put the thread into the content. This can allow vapors in addition to germs into the inside of the fit. Sealed seams have cementing or special tape warmed up and ‘welded’ over the seams so that there are no openings.

When protective material will be tested, it has a breakthrough as well as a permeation rate. The particular breakthrough time involves the amount of time a chemical takes to get detected on the inside of the material. The particular permeation rate is how much time the chemical requires to be able to soak to the other side in the material in the plastic fit.

Rules And Regulations

Level D Suits – The National Flame Protection Association has set up a collection of standards for protective apparel to follow. These regulations let you know what you should be looking for the strength, resistance, and features that each piece of protective item is supposed to have as well as their particular durability. When looking at protective apparel, it is also helpful to look for it is rating and the Safety Products Institute seal on the apparel.

It is important to save money and be cozy in a protective suit, just about all needs to have an adequate level of basic safety for the job you are doing. Make a decision on what level of risk your needs poses and what kind of safeguard you need. The right plastic fit can make all the difference when it comes to getting a healthy and productive life.