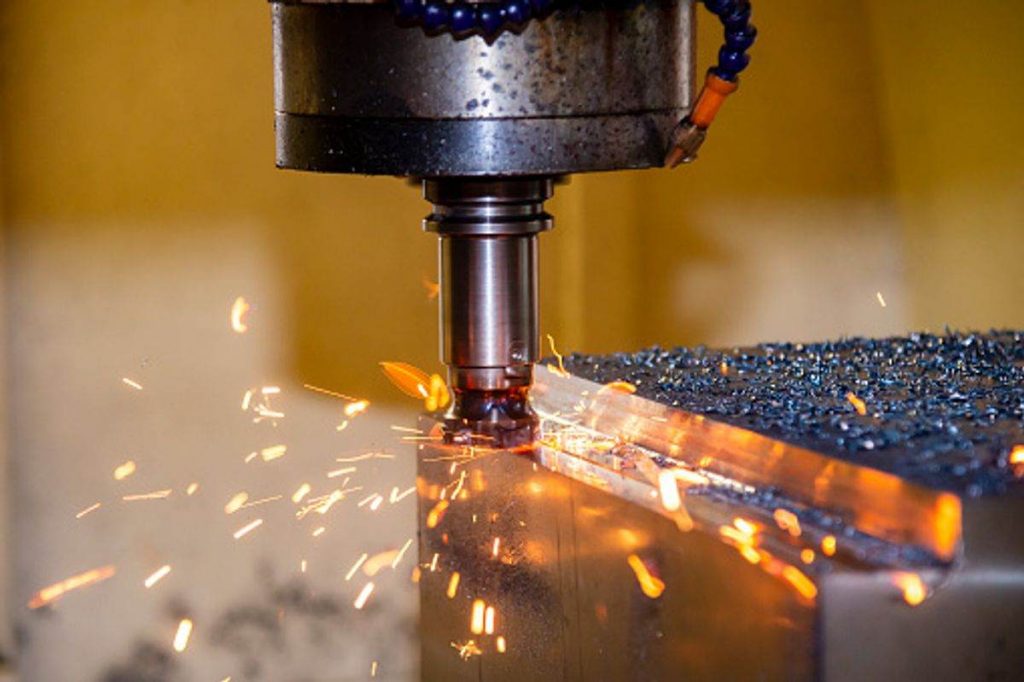

CNC machining refers to any method that uses a CNC appliance. This could be for routing, milling, drilling, or other types of doing the job that is done with metal, real wood or other materials. This is a developing process that often uses the automatic opportunity from the laptop or computer to create shapes or sorts that must be precise. What is the perfect way to find the CNC METAL MACHINING?

Raw materials are being used, and they are put into a CNC machine that uses chopping tools to make these patterns. The CNC machining method involves computers with one or more microprocessors and several units regarding storage. With CAD or perhaps CAM software systems included in CNC, the computer can be developed to produce the precise movements that can create the part.

In CNC machining, the process is robotic, saving the owner time and business funds. The operator can fill up the materials, program the appliance, and then work with no attention when set up effectively; the amount of time it is working without attention is also developed.

An important aspect of virtually any CNC machining is for the particular operator to know the machine properly. CNC is an addition to the general characteristics of the device. For example, incorporating CNC into the process automates it if you are doing a routine. However, for that operator, they need to understand the machine, how to store codes or use CAD or CAM and how to work the machine; they must also learn how basic routing works.

One more important area so that you can understand CNC machining will be the basic components of the machine. You should know how these machines work to fix them if anything goes wrong. This also enables the operator to understand the device’s constraints and capabilities to get the most out of use.

As CNC machining becomes a project, the driver is in charge of defining five areas. They will first consider the project they want to design and plan it out. This is where seated and drawing out programs will be a good idea.

The next region is to understand CAD to translate the drawing into the pc and then understand CAMERA to translate the CAD information into machine dialect. In the final area, the person must realize the Controlling functionality to make the machine do what is required. When all these places are fulfilled properly, they allow the individual to create the actual project in the way they noticed it in their drawing.

CNC machining was traditionally done in commercial settings and very large CNC machines. These days, mini-CNC devices allow the process to be carried out on a smaller scale within a home workshop. This has permitted the smaller business to make the most of building a variety of parts and products that were not formerly available except on a bigger scale.

CNC machining produces simple and complex styles and can be used on various components, including aluminium, foam, wooden and other metals.

Read Also: CNC Machine Advantages